High-precision processing and high-level quality control systems

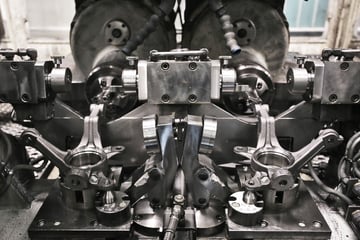

Knuckle arms, damper forks, and lower control arms are suspension components that determine a car's comfort and how it feels to ride.

Because these important components underlie automobile driving, stopping, and turning functionality, they require a high level of precision machining. Automation is being pursued through the implementation of robotics, and on all production lines, all processing is completed after just one installation phase, thereby managing to both save labor and increase precision.

Additionally, a high level of quality assurance is maintained for automatic bush insertion machines produced in-house through the detection of angles and component type.

Undertaking the challenges of precision and weight reduction

Tsuzuki Co., Ltd. pursues both greater precision and weight reduction as it continues to provide a reliable level of quality and maintain high levels of efficiency, productivity, and precision.

Tsuzuki Co., Ltd. utilises CAD/CAM systems and its YASDA five-axis machining center to achieve extremely high-precision machining with the minimum number of processes. Our prototyping department contains a line-up of five-axis machining centers of differing specifications, and we also engage in highly difficult types of processing.

Beginning at the product development stage, we make proposals and suggestions for further increasing product quality by using cutting / interference simulations to speed up the prototyping process and achieve more productive specifications, while also taking mass production capabilities into account.

Integrated function-assurance system

In order to develop and mature its integrated function-assurance system that extends from the processing phase through assembly, performance tests, and coating, Tsuzuki Co., Ltd. has achieved a production line layout that improves the rectification and efficiency of product flows and worker movements. We work to make progress and object tracking more visible, from component to product, and improve the quality of our management.

We also work to minimize production loss by exchanging blades used in the production of rotor shafts, which is a process that involves rapid blade wear due to the use of hard materials that are difficult to cut. For very low-tolerance processes, a high level of process-assurance capability is maintained through total 100% measurement and feedback.