Production equipment and quality control underlying mass production

Tsuzuki Co., Ltd. is pursuing the full automation of its machining processes to achieve internationally competitive costs through high efficiency and productivity, while also maintaining reliable product quality. Tsuzuki production lines that have implemented advanced automation technology include the lines manufacturing knuckles for four-wheel automobiles, automated spindle grinding lines, and CVT stator shaft machining lines. These lines utilize computer-based production management systems to provide reliable components in a timely manner.

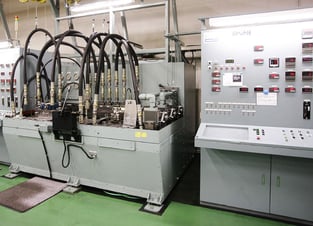

In Tsuzuki's production of hydraulics equipment for construction machinery, we strive to achieve proper temperature management and cleaning for processing lines, and with improvements to processing technology we have achieved outstanding processing precision. We engage in production utilizing an integrated quality control system that combines processes from machining at a machining center through to assembly, performance tests, and coating.

Main equipment

Automatic shaft bend corrector

Cylindrical grinder

Automated spool lathe line

Walter tool grinder

Five-axis machining center

Knuckle transformer machine

Automated rotor shaft machining line

Automated stator shaft machining line

| Equipment name | Number of units | Manufacturer |

|---|---|---|

| Transformer machine | 8 lines | Honda Engineering Co., Nachi-Fujikoshi Co., Takusei Kikai |

| Vertical / horizontal machining center | 116 units | OKK, DMG Mori Seiki Co., Yamazaki Mazak Corporation, Hitachi Seiki, Yasda |

| CNC lathe | 24 units | DMG Mori Seiki Co., Murata Manufacturing Co., Nakamura-Tome Precision Industry Co., Yamazaki Mazak Corporation |

| CNC grinding machine | 15 units | Okuma Corporation, Mitsubishi, Minakuchi, Tsugami, Micron Machinery Co. |

| Hobbing machine | 5 units | Kitai Sangyo Co. |

| General-purpose machines (milling, grinding, lathing) | 86 units | - |

| MIG/MAG welder | 9 units | Matsushita |

| High‐pressure cleaning machine / oscillating cleaning machine / etc. | 74 units | Sugino Machine, Morigo Seiki, OGA, Kan Manufactory Co. |

| Hydraulic pump / test bench for valves | 22 units | Komatsu Engineering |

| Automatic leveler | 4 units | Towa |

| Assembler machines | 9 units | Produced in-house |

| Heat treatment / high frequency | 2 units | ESCO Ltd. |

| Heat treatment / gas carburizing furnace | 2 units | Oriental Motor |

| Coating line | 2 lines | Meiji Machine Co., Dainikka |

| Coordinate measuring machines | 4 units | Tokyo Seimitsu, Mitutoyo |

| Surface roughness measurement instruments | 3 units | Tokyo Seimitsu |

| Universal testing machine | 1 unit | Shimadzu |

| Roundness measuring instrument | 2 units | Tokyo Seimitsu |

| Thermal deburring machine | 1 unit | Extrude Hone |

| Five-axis machining center | 4 units | DMG Mori Seiki Co., Yasda, Yamazaki Mazak Corporation |

| Multitasking machine | 1 unit | DMG Mori Seiki Co. |

| Tool grinder | 5 units | Walter, Makino |

Quality control

Stator shaft clean room

Mini-pump test bench

Mid-size pump test bench

Large pump test bench

Coordinating measuring machines

Roughness measuring machines

Roundness measuring machines

Shape measuring machines